Air is a vital part of our life. That is why we care so much that the air we breathe in the rooms where we spend most of our time is free of pollutants, dust, and allergens. This story is about two Ukrainian companies that create innovative ventilation solutions. PRANA produces air recuperators with copper heat exchangers, which endow the product with antiseptic properties. And VTS Complecte is working on eco-friendly household ventilation units with corrugated cardboard casings.

An adult at rest inhales and exhales an average of 7-8 litres of air per minute, which is approximately 11,000 litres of air per day. Normal air in our environment consists of several gases: 78% nitrogen, 21% oxygen (the minimum concentration needed for humans is 19.5%), and 1% carbon dioxide and other impurities. The exhaled air has about 15% of oxygen, so about 5% is consumed with each breath and converted into carbon dioxide. Thus, a person uses about 550 litres of pure oxygen per day.

Smog, dust storms, vehicle exhaust and industrial emissions — all of these increase the air quality index. During the day, an average person inhales 20,000 litres of air, and with it the harmful substances that impact one’s well-being. It makes us think: if the air outside is polluted, is it much cleaner and safer inside? Unfortunately, it is not. The concentration of pollutants inside buildings is usually 2–5 times higher than it is outdoors.

Human breathing causes high concentrations of carbon dioxide (CO2) that significantly affect the hygienic value of air. Because of the high level of CO2 a person can experience shortness of breath, discomfort, headache, redness and tingling in eyes or a cough. If the level of CO2 is 0.04-0.043% outdoors, inside the premises with people it reaches over 0.15%.

Modern ways of insulating houses create a thermos effect. Plastic windows and doors are a barrier to the natural ventilation of the room. Consequently, the air inside houses and offices stagnates, and this only contributes to the spread of harmful substances and bacteria. Normal ventilation is ineffective because the same harmful substances enter the room along with the fresh air from the outside. Dust, plastic and fumes from furniture made of particleboard or fibreboard, carpets, linoleum and laminate floors also reduce the air quality.

There are several ways to clean the air in a room: through natural methods and materials that absorb unpleasant smells or harmful substances (houseplants, essential oils, salt lamps, etc.), and through artificial ones, such as, air cleaners, ventilation systems and air conditioning.

Air cleaning by ventilation systems

Only a comprehensive national and international policy can solve the problem of air pollution globally, but it is possible for many of us to provide clean air at home or in our offices. If up until the 19th century the indoor ventilation was mostly done through natural airing, today we have various types of ventilation systems, in particular recuperation units. They provide a complete air exchange, maintaining the temperature in the room and not requiring any significant electricity consumption.

The working principle of the unit is that the heat of the outgoing air (exhaust air that is extracted outside) is used to heat the incoming air (fresh air that is introduced into the room). This method is much more efficient than natural airing, because it keeps the heat in the room and then reduces the heating costs. In winter, up to 30% of heat is lost through open windows, and in summer about 70% of electricity is used for air-conditioning of the room. Therefore, on hot days, the work of ventilation units is no less effective, because it saves the amount of energy required for cooling the air in the rooms, which in turn allows people to use the air conditioners with less power.

An air conditioner with climate control function is a device that cools down or heats up the air, but does not enable its exchanging. The air recirculates and changes its temperature, balancing the humidity in the room. A recuperator, however, replaces the air and maintains the comfortable temperature created by the air conditioning or heating system. This is the main difference between the two devices.

It is best when the air conditioning or heating system and the recuperator work in harmony in the room.

Prana Lviv Company

PRANA is one of the most successful Ukrainian companies in the field of air ventilation, and also is the author and manufacturer of a number of modern energy-saving technologies, including recuperators. The company’s specialists also analyse various energy-saving technologies, in order to implement them into production processes and products in particular.

The company’s activity has long ago expanded beyond the borders of Ukraine: the map of its offices currently covers 38 countries. The main exports are to European countries.

It all started around 20 years ago with a group of entrepreneurs who produced gypsum based thermal insulation panels that were safe for people. They were used for indoor and outdoor insulation and room division.

In their work, the specialists were constantly facing high indoor humidity, mould and fungus problems. In their search for an effective solution, they realised that the main reason was the lack of quality ventilation with recuperation, which prompted them to develop in this direction. Subsequently, the demand for their recuperators exceeded the demand for other activities of the business. This is how PRANA was formed.

Their motto is, ‘The right way of breathing’. The philosophy promoted by the company is aimed at energy saving, human health, zero waste production and the use of harmless materials and boils down to one thing — the harmonisation of man and nature.

At present, about a million people in the world use the products of the Ukrainian company PRANA. It cooperates with local and international funds. The company’s founder, Roman Kuzych, is sure that their success depends on perseverance.

“In our first years of working, we learned that if we do our work well, the financial result is sure to come.”

Air recuperators with copper heat exchangers

The PRANA recuperator is an innovative system with a built-in innovative supply and exhaust ventilation system with heat recovery. The air supply and extraction take place simultaneously without the airflows mixing. The casing of the ventilation system is made of food-grade plastic and the heat exchanger is made of copper. According to Roman, this makes the PRANA technology unique:

“We are the only company that uses copper as a heat exchanger material in recuperators. Because we did not just take the path of energy saving and comfort, we also opted for safety. After all, copper has been used for centuries as a natural antiseptic. Neither germs nor bacteria can live on this material. In addition to antiseptic properties, copper is an effective heat conduit.”

Recuperators are produced in Ukraine, in Halychyna, and some components are bought in the Netherlands, Austria, Germany, Malaysia and China. According to the manufacturer, the service life of the devices is unlimited, and the estimated lifespan is about 30-40 years. The company’s first recuperators, sold 15 years ago, still work effectively. The price range is from budget versions to more expensive ones. For example, a recuperator for the domestic sector will cost between €300 and €900. Power consumption of such a device is equal to that of a light bulb — 5 to 50 W. Another significant advantage of a PRANA recuperator is its coefficient of performance (heat preservation) of up to 95%.

Ventilation trends

When PRANA started out and presented its first recuperators at trade fairs, it brought a smile to the faces of sceptics. After all, at that time, large ventilation systems were developed actively and it was a real challenge to compete with them. However, the business that PRANA started 15 years ago has now evolved significantly and continues to improve every year. Roman believes that they owe their success to their customers:

“The trend has evolved thanks to the users. Over the years, more and more dealers and partners have approached us precisely because their customers have asked if they have PRANA. We started by gaining the trust of the users, and it paid off. People became more and more interested in the technology.”

PRANA specialists were giving thematic lectures at universities and disseminated information via media and Internet to inform the potential consumers about the causes of air pollution and its negative effects on people. Thanks to these educational activities, PRANA products have become recognisable and in demand.

The company regularly updates and improves its devices. PRANA is now producing its fourth generation of recuperators. This is aided by the feedback from users, which for PRANA is a valuable source of information, just as it was in the beginning of their work. Feedback is taken into account when upgrading and improving the models, as the company does not plan to stop there. In addition, the company has its own climate laboratory, which allows them to test and improve existing models of recuperators and helps to develop new ones.

Now the company produces three series of recuperators: domestic, semi-industrial and industrial. The devices are equipped with moisture, temperature and CO2 sensors that react to radon (a radioactive gas), carbon monoxide and other harmful substances.

PRANA took part in the Climate Innovation Vouchers projects. This initiative is implemented by the PA Greencubator together with the EBRD as a part of their Climate Technology and Finance Transfer Centre (FINTECC) programme, funded by the European Union. An innovation voucher from the EU and EBRD has made it possible to improve PRANA recuperators with smart control functions. Thanks to this technology, it is now possible to automatically select the unit’s operating mode based on the room’s air quality, maintain the required level of excessive pressure, monitor the level of filter fouling, integrate into smart home systems and more. The combination of these options has increased the efficiency of the PRANA recuperator to 95%. Roman notes that thanks to this cooperation, the company has improved its image and strengthened its credibility both in the Ukrainian and international markets:

“The trust of partners, dealers and like-minded people that we acquired after joining the programme was partly reinforced by the support from Greencubator. Also, thanks to our cooperation, we have been able to expand our budget a little bit and pay more attention to the European requirements for the products we produce.”

The clients

Customer focus is a priority for the company. Before installing a recuperator, the company experts try to provide comprehensive advice to a potential user. They investigate the environment of the premises to be ventilated and find out what problems need to be solved. Roman explains that this helps to ensure that the equipment is properly completed to clean the air as effectively as possible:

“Recuperators not only address obvious problems, such as high humidity, mould, fungus and polluted air, but also more trivial but no less important issues: whether or not people have a good quality sleep at night and what kind of mood they wake up in. After all, it is about people’s comfort and health.”

Anna Hrynyshyn, the owner of a basement flat in a house in Lviv, turned to the company because of a mould problem. Due to its non-standard location, the air in the flat was stale, and because of the condensation and capillary action of moisture from the ground the humidity level was high. Roman explains how they helped Anna solve the problem of dampness and mould:

“Those points about condensation are solved by the recuperator, absolutely. The problem of capillary traction still needs to be solved by waterproofing, but the recuperator allows you to at least remove all the symptoms.”

Apart from the recuperator, there is also an air conditioner in Anna’s flat. Together, these two systems create a comfortable environment. The windows are always closed. The owner says that natural ventilation is no longer necessary:

“The recuperator works all the time — and there is fresh air all the time. The air is no longer stale as it used to be, it’s not musty or mouldy anymore. That means you can breathe freely. And also the level of humidity is now lower, so the laundry can dry out. There is no feeling of lying in a wet bed anymore. It is also very energy efficient, because the utility bills have decreased and we are happy, overall.”

PRANA produces about 15,000 recuperators during the year. Its customers range from residential to commercial, agricultural and social sectors. For example, one of the company’s clients, Tetiana Domashovets, is the owner of a print shop in Lviv. The premises needed ventilation to remove airborne pollutants from the production equipment and at the same time to supply fresh air for the employees to work comfortably. The owner of the print shop says that they now use the PRANA recuperator in different modes, depending on the time of day.

According to Roman Kuzych, during the COVID-19 pandemic the number of requests from medical institutions has increased:

“These are enquiries from Ukraine, Italy, Poland and other countries. Because it turned out that this virus does not live for more than 4 hours on copper (according to US laboratory research — ed.).”

PRANA recuperators have the State Sanitary and Epidemiological Examination Certificate of 2019 and the European Hygienic Certificate (Poland). These documents confirm that the units comply with all safety requirements and standards, while the Hygienic Certificate also confirms the validity of PRANA recuperators for use in healthcare facilities.

Protecting the environment

Thermal power plants (TPPs) are the main source of thermal energy in the world. Coal and natural gas are burned to generate energy, which pollutes the atmosphere and increases the greenhouse effect. PRANA recuperators store up to 95% of the heat, thus using less fossil energy for heating and contributing to the reduction of greenhouse gases in the atmosphere. One recuperator reduces up to 1,134 kg of CO2 emissions per year. In total, the PRANA users community has already reduced potential global CO2 emissions by 169,000 tonnes. This is one of the company’s significant achievements that it is most proud of.

In autumn 2020, the company’s management signed an agreement with Meest company to provide delivery services with zero emissions of greenhouse gases. The essence of the service, which is called ‘Green Delivery’, is that PRANA tops up all recuperators delivery costs with a small extra amount. These funds will be used for CO2 sequestration projects. This eco-initiative of Meest is implemented in cooperation with EBRD and Greencubator and aims at engaging with many other Ukrainian businesses.

In addition, PRANA takes back all recuperators that, for whatever reason, have become unnecessary to the users. Generally, in such cases, the units or their components need to be refurbished. After some re-refitting, the recuperators are returned to use. Roman notes that all elements of which the recuperators are made are recyclable in any country:

“We gladly take it all back, give it a new life — provided the damage is not of a mechanical nature.”

VTS Complecte — a company from Dnipro

VTS Complecte operates in the commercial ventilation market segment and makes automated systems for ventilation. Co-founder Mykhailo Makhlevych says that the company was formed in 2007 as a regional office of the European company VTS Group, where Mykhailo and his colleagues used to work. The company evolved and launched its own ventilation automation system the following year.

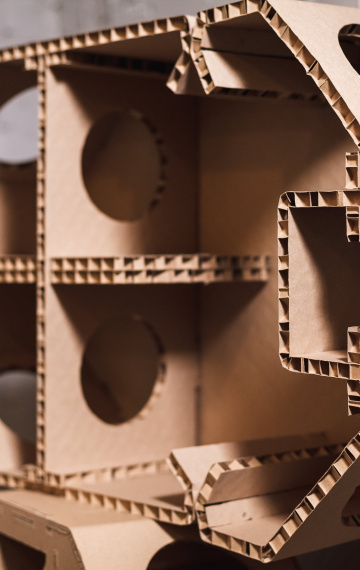

In 2014, the Ukrainian company took part in an internal corporate competition, where Ukrainians made a significant number of suggestions to improve the design of the equipment and emerged victorious. This gave rise to the innovative and unique Cardboard AHU (Air Handling Units) project. This was an ecological household ventilation unit with high energy efficiency. The maximum effect is achieved thanks to the enthalpy recuperator and the copyrighted control strategy at low outdoor temperatures. And the recuperator casing is made of durable cardboard. Mykhailo Makhlevych told how it all started:

“After winning the competition, I started experimenting with different materials to produce the ventilation unit. I shared the idea of creating the units from corrugated cardboard with a friend of mine, who is the executive director of a cardboard packaging company. He cut out a prototype based on my designs in an experimental production facility, and this was the impetus for further development of the idea.”

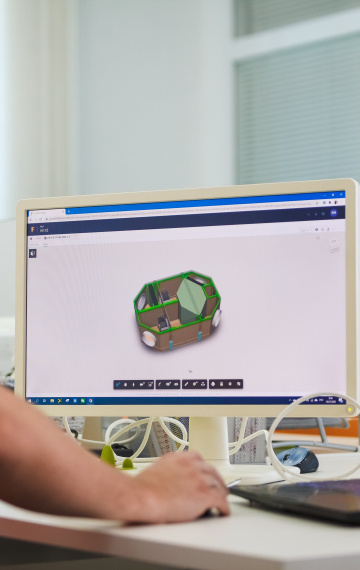

Cardboard AHU received a grant as part of the Climate Innovation Vouchers project run by NGO Greencubator with the support of the European Bank for Reconstruction and Development and the European Union. VTS Complecte has begun collaborating with the ARTKB industrial design bureau on the design, prototyping and testing of the unit. Mykhailo Makhlevych points out that the developers are now at the stage of preparing for serial production.

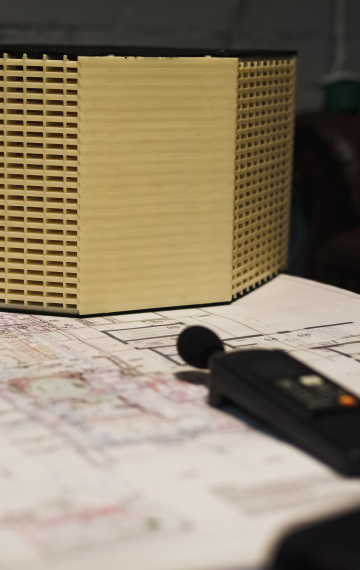

Cardboard AHU units are unique products on the market. The main feature of such recuperators is their casing made of structural types of cardboard with a special water-resistant coating. The use of honeycomb or corrugated cardboard significantly reduces the cost of the unit, because for domestic devices making the casing is the most expensive and energy-consuming stage. Another advantage is lower CO2 emissions produced by these systems as opposed to the classic technology (steel and plastic).

“Honeycomb cardboard is a very robust and environmentally friendly material that is also soundproof. It does not require a lot of energy for its production and finishing process. It is also easy to dispose of or recycle.”

The aim of the developers is to make a product that is affordable to everyone. These ventilation units are designed for private households and small businesses. According to Mykhailo, an expensive product cannot become widely adopted. That is why they were looking for a way to reduce the cost of an air handling unit without losing its efficiency and quality.

VTS Complecte developers are convinced: potential customers realise that thanks to ventilation they can get fresh air without dust and avoiding draughts, while saving the family budget significantly on heating and air conditioning.

Honeycomb and corrugated cardboard ventilation units

The development of the mechanical design of the Cardboard AHU project is overseen by Mykhailo Babychenko, Technical Director at the engineering company ARTKB. He said that creating the Cardboard AHU was a real challenge: it was necessary to do something that no one had dared to do before:

“It was a very interesting project. We worked on it for quite a long time because we had a lot of complicated moments in terms of product development. We had to combine things that did not fit together, or had never been combined before. The main challenge of this task was to really combine the material used for packaging with the device that provides ventilation for the rooms.”

The company’s experience in designing global products, together with the industrial design office of ARTKB, contributed to the development of the ventilation unit prototype. Mykhailo Makhlevych says that thanks to their advice, he has rethought a lot and paid attention to details he had not paid attention to before:

“The start-up world is different from the construction market in Ukraine, where I work. So in many ways, our cooperation was like an enlightenment for me. In addition to their core functional responsibilities (mechanical design, planning and unit development), they (the industrial design office team) also opened up related niches: how to prepare properly to enter the market and start production.”

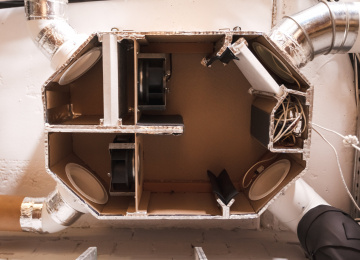

In modern insulated homes, the energy costs for ventilation make up 40 per cent or more. With the Cardboard AHU, this can be reduced up to 4 times compared to conventional ventilation. The system of filters protects premises from dust, including pollen. The use of UV lamps in the recuperator reduces the risk of spreading viruses indoors. Thanks to the cardboard frame, which has noise insulation properties, the recuperator can be used comfortably at night. Mykhailo talked about the functional diagram of the ventilation unit:

“The heart of the unit is of course the recuperator. In this device, two air flows — external and internal — are let inside and without mixing they exchange the energy. If the room temperature is high and the temperature outside is low in winter, thanks to this energy exchange we have a temperature of about 16-18 degrees Celsius reaching the room. And this is already comfortable enough.”

The unit has DC (direct current) motors and high-efficiency fans. Another functional element of such a unit is its filters, which differ in sizes. The aim of the designers is to ensure the same service life for all elements. So, the owners will only need to have service work done once a year.

Dealing with humidity

There is a stereotype that humidity has a detrimental effect on cardboard. However, VTS Complecte is convinced of the contrary. After all, there are many types of cardboard that deal perfectly with humidity or even prevent it. Mykhailo also points out that where high levels of condensation are expected, the casings are always treated with modern materials that protect the most vulnerable parts of the device:

“The automation system includes what is known as a leakage protection. The unit is equipped with a sensor that monitors that humidity does not occur in large volumes. In other words, there are several levels of protection: the material itself is robust, the parameters of the areas that can become damp are monitored, and an additional finish is applied.”

As a result of their tests, the developers came to the conclusion that it was necessary to combine different types of cardboard in order to get the top quality casing.

Mykhailo Makhlevych jokes that they are even ready to create installations for exhibitions, where the casings are immersed in aquariums to demonstrate the material’s resistance to moisture. And when asked, “What is so innovative in those recuperators?” he replies:

“Recuperators have been produced since about the sixties, but all these devices are archaic in their design. They are not environment-friendly or recyclable. What have we achieved? We use paper. Why should we make a casing out of plastic, metal or various polymers? We decided to use a new material, and to make an effective form for it, an effective design.”

Future plans

Currently the developers have only prototypes of their ventilation units. Their components are made in Kherson and Dnipro, Ukraine, and some are imported from Korea and China. Mykhailo dreams that serial production will be fully concentrated in Ukraine:

“By nature, I am a kind of ‘improver’. If I have an opportunity to improve some products and to create something that benefits our community — this is very important to me. My goal is for my business to become a small stepping stone in the technological revolution that will lead humanity to a higher standard (of living).”

The service life of these air handling units is around 10 years. It is true that the developers have not yet come to a single option, as there are prototypes with different lifetimes:

“Either we increase the service life of the casing through additional finish (but the life span will still be limited, because of the recuperator’s membrane) or the service life of the unit casing will become shorter, but it can easily be replaced and disposed of safely. In either case, the ventilation unit can be used for 5 to 12 years.”

The next stage for VTS Complecte is to establish production, as both Ukrainian and European customers are already showing interest in the product.

Mykhailo Makhlevych is convinced that a new market is now forming, where the household ventilation units will become indispensable:

“This is the prospect of the next five years. Everything is heading towards a trend when every house or flat will have their own centralised or decentralised ventilation units. In either case, ventilation will be applied as required. I believe that houses should have quality ventilation.”